I actually ended up getting 3 wooden build-it kits by the Chinese company, ROKR. The first one was the Treasure Box, and this one is the Airship. It’s advertised as being 300 mm x 215 mm x 250 mm (approx. 11.75″ x 8.5″ x 9.5″), so it’s fairly large for what you get. ROKR makes a big deal about the kit containing 7 sheets of pre-cut plywood, but the seventh sheet is pretty small and almost shouldn’t be considered part of the count. There’s also a small collection of steel pins, plastic caps and spacers, a wind-up spring and spring key. I’d guess that the package started out weighing at least 2 pounds (Amazon shows the shipping weight at 2.9 pounds, so I’m not too far off).

I got about 10 minutes in on the dirigible assembly before I remembered to take a process photo. See that stack of disks and pieces to the left, above? That’s all scrap.

Notice the ruler at the top, and the weird stand thing to the left. This kit has a LOT of support tools used in the building of this thing, that aren’t part of the finished airship. The ruler lets you check the lengths of the steel pins and push pieces together, and the stand is used for placing the spacers at the correct distances from the ends of the pins. There are 5 stands of varying height, plus one simple flat disk, for space placement. There’s also a 2-layer plate assembly used at the end for supporting the paddlewheel centers when mounting them on the axels. Pictured above are the parts used for making the dirigible nose propeller.

Finished propeller, plus airframe skeleton disk parts.

Finished prop gear subassembly.

Airframe drive gear parts.

Finished drive gear subassembly.

Nose subassembly, with propeller and airframe supports and drive gear.

Dirigible assembly, with nose subassembly and drive gear fixed in place.

Dirigible with the top, bottom, left and right outer skeleton frames in place, along with the tail ladder. The strips will be inserted through slots in the ribs to make the assembly look more like a balloon.

Finished airballoon assembly. The instructions state that it’s ok to use wood glue to fasten down loose parts. And, one of the strips kept pulling out of its notch in the nose rib. Otherwise, all the strips and other pieces forcefit into place just fine. It took me 3 hours to get this far, largely because I was making beginner-level mistakes and having to disassemble part of my work and reassemble it to fix my errors. I’d started at 10 PM, and decided to quit for the night at 1 AM. (That, and I wanted to go to the store to get some wood glue.)

Starting back up the next day. A lot of these pieces require significant force to slide the tabs into the notches. That, and serious patience (especially those long, thin strips for the dirigible body). I did manage to crack one of the tail fins on the dirigible, but I was lucky in that the crack isn’t noticible unless you know where to look. Otherwise, I’m extremely surprised that I didn’t snap stuff in two with all the pushing I was doing. My fingers still hurt two days later.

Shown above, the ship front left body plate, front wheel assembly, and part of the upper deck.

There are literally a boat-load of gears for this thing, and most of them have to be assembled before doing anything further on the boat body. Above, gear assembly 1. Note that the two smaller gear pieces are not mirror-reverse images of each other. It is possible to put them on the gear shaft wrong so that the teeth are not direct aligned with each other. If this happens, flip one of the gears over and try again.

Parts for gear assembly 2.

Finished gear. This one connects to the two big paddlewheels, later.

This is my favorite part – the ratchet box assembly. Unfortunately, when the cover plate is snapped in place on the box, the ratchet (the 4-armed thing in the lower right corner) gets hidden.

Finished ratchet box, with spring pin.

Parts for gear assembly 3.

Finished gear. Notice the positioning of the spacers. This is what all those little adjustment stands are for.

Parts for the main spoke gear. This is the biggie that drives a lot of the other gears.

Finished main spoke gear, plus spacer spacing stand 4.

Parts of the rear wheel and rudder subassembly.

Finished tail.

Tail drive gear assembly parts. Note that the half-gear disks are strictly ornamental, and don’t actually turn or anything.

Finished tail drive gear subassembly.

Parts for the tail propeller.

Finished tail propellor, plus the tail drive gear and tail wheel subassemblies.

All three pieces set together in position.

Taking the above body plate, mounting the tail assembly, paddlewheel gear, and spring in place.

Now, with the ratchet box on top of the spring. This was kind of tricky, in that the notch in the end of the spring pin needed to hook into place on the spring as the box was set in place.

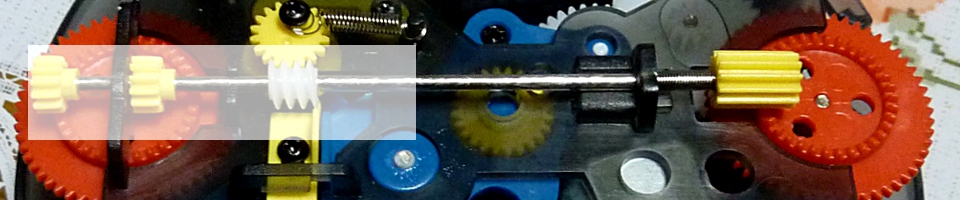

All of the other gear assemblies are now in place. One of the things I was surprised by for this kit is that while it includes a small tin of wax, there are no indications anywhere in the manual that any of the moving parts need to be waxed at all. I did use candle wax on the paddlewheel gear plate and the matching hole in the body plate, above, but otherwise the kit didn’t seem to need waxing, and I didn’t bother doing it to any of the other gears or surfaces.

Ship body, with the upper front and back deck subassemblies in place (see below for placement).

The ship main body, with the right body side plate snapped in place. This step took some time, because the pins and tabs of the gears and decks didn’t want to align with the side plate notches.

Other side of the current subassembly process.

Parts for the air duct thingie that ships have. Again, the half-gear piece is only for decoration.

Finished thingie subassembly.

Finished paddlewheels, and mounting support plate. I didn’t bother taking process photos for this step, because I figured I already had too many photos by now. The mounting support plate is set under the center of the paddlewheel first, then the ship is set above the wheel so that the wheel axel tabs can be put into place in the wheel. Otherwise, pushing down on the axel would damage the center of the wheel spoke piece.

Putting the dirigible on the ship main body. Note that there are only two sticks supporting the dirigible on the ship decks. This means you have to be careful while handling the airship to prevent snapping those sticks in half. Note also the white plastic ribbon. I’d glued the loose end of the one strip into its notch in the nose of the dirigible, but it was just taking too long for the glue to dry and I was bored with having to sit there holding the strip in place for an hour. So, I took the ribbon (which is used as string in Japan) and tied the strip down against the nose this way. I also took the opportunity to apply glue to all the other strip ends as well, just to make them less likely to pull free later on.

The tail wings. The two little disk pins on each wing are notched off-center, so the wing pieces look like they’re slightly downwardly curved. I think this is a nice touch.

And, we’re done. One thing I’m not as happy with regarding the instructions is that there’s nothing showing how to wind up the spring, how to hold the wheels to keep them from moving as you turn the key, or how many turns to make without damaging the spring. All the parts move freely, so that’s good. I’ve been able to turn the key 5 full rotations, and that gives me a running time of about 5 seconds, with a full distance of over 10 feet (I can’t be precise here, because my apartment is small, and the airship runs into the wall before the spring fully unwinds. I’m thinking that it might be able to cover 20 feet before stopping.) There’s a little wooden lever at the left of the back deck, but I’m not sure what it’s for. It seems to engage and disengage one of the gears, but I’ve tried sliding it back and forth while letting the airship run and I haven’t noticed it having any kind of effect on anything.

The ship took another four hours to build, so all-total I’d say this was a 7-8 hour project. If I tried it again, I might be able to bring that down to 6 hours. As I say, there wasn’t any need for the tin of wax, or the little scrap of sandpaper. There were a lot of extra parts in case something broke or got lost along the way, but I didn’t need any of them. There was also a HUGE amount of scrap wood left over – maybe 1 pound worth. But, it was fun to build, and I’m waiting for my English classes to start up so I can show it off to a few of my students.

This airship is a novelty item, and doesn’t have a lot of replay value. Just put it on a shelf and show it off to your friends at parties. Although, you can run some LEDs through the dirigible, if that’s something that appeals to you, and use it as a Christmas decoration for next year.

“Look! On the ground! It’s a dog! It’s a shoe! No, it’s super shoedog!”